PIN PETROCHEMICAL CHEMICAL & ENERGY Publication

ASTM D6304 outlines standardized procedures for determining water content in petroleum products using coulometric Karl Fischer (KF) titration. Revised in November 2020, the method now includes enhanced guidance and additional techniques for broader applicability across sample types. This article summarizes the key principles behind each procedure (A, B, and C), compares their strengths, and highlights ECH’s innovations that support these standards.

Procedure A – Direct Injection

Procedure A is the traditional direct injection method, best suited for light liquids and fuels without interfering substances. A known sample volume or mass is introduced directly into a pre-conditioned titration cell, where moisture is measured via the KF reaction and reported in ppm, %, or mg/kg. This approach is well-established and serves as the baseline method in many laboratories. ECH’s Aquamax KF Plus has been fully compliant with Procedure A since its inception, offering reliable, accurate results for routine moisture analysis.

Procedure B – Automated Headspace Technique

Procedure B introduces headspace sampling, in which the sample is sealed in a vial and heated within an oven. As moisture evaporates, it is carried by a dry, inert gas (e.g., nitrogen, argon, or pre-dried air) into the titration cell. This method is particularly advantageous for automation, with several manufacturers offering autosampler integration.

ECH’s Aqua 40.00 Vario, featuring a closed-loop carrier gas system, extends reagent life significantly—often allowing over 1,000 analyses per charge—making it highly efficient compared to typical systems. Procedure B is ideal for laboratories handling a high throughput of diverse samples.

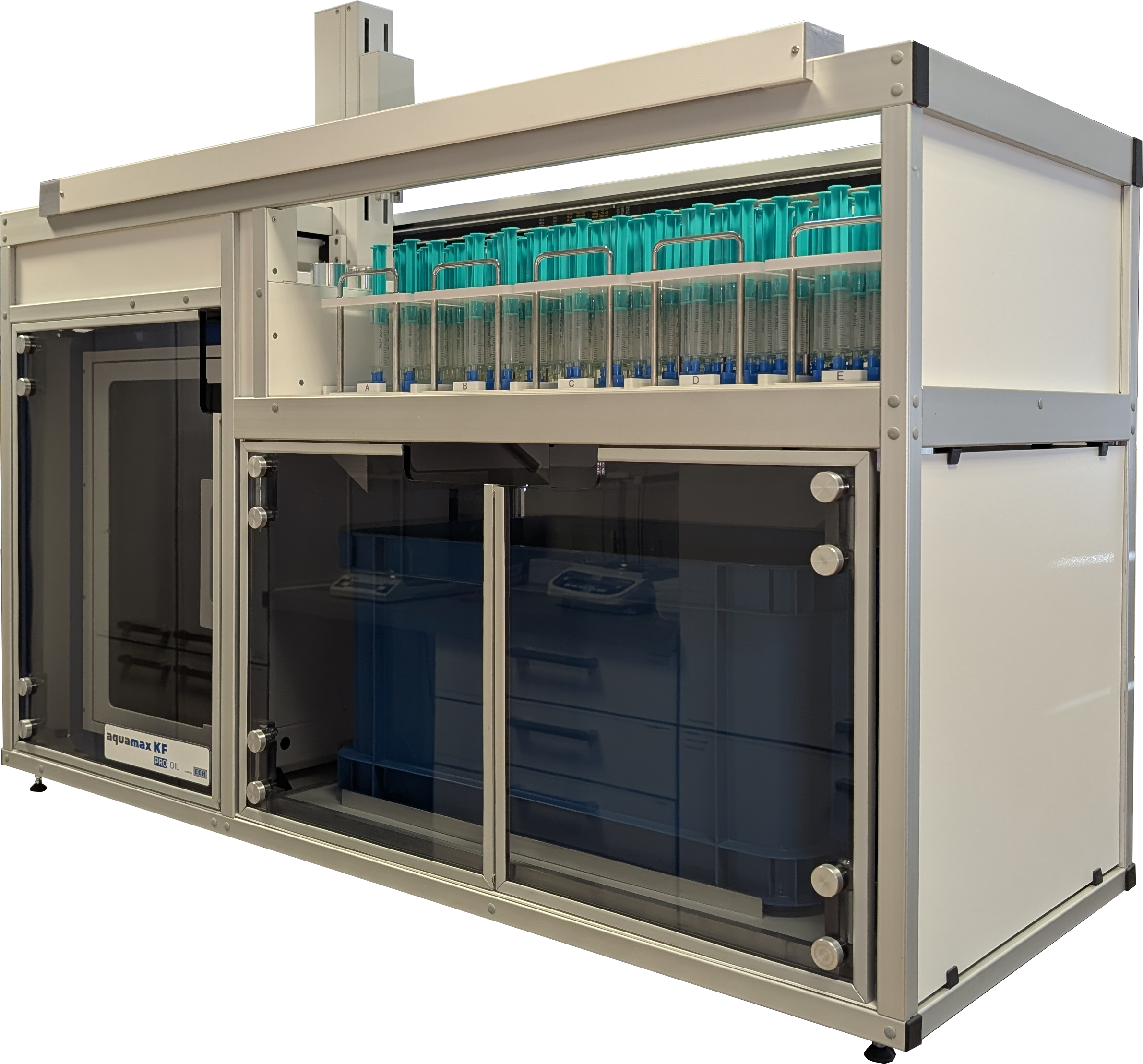

Procedure C – Oven Evaporation with Direct Injection

Designed for samples with low water content, Procedure C also involves heating but uses direct injection into a sealed evaporation chamber. Moisture is vaporized and transferred by dry gas into the titration cell. The remaining sample stays in the chamber and is removed automatically. Unlike Procedure B, no blank correction is required, improving reliability in low-moisture samples.

Repeatability data shows that Procedure C delivers the highest level of accuracy among the three techniques, making it the preferred choice when precise moisture quantification is critical. Combined with high sample throughput capabilities, Procedure C offers both efficiency and analytical confidence for demanding petroleum applications.

The Aquamax KF Pro Oil and Pro Oil Auto systems from ECH are specifically designed to fulfil all the requirements of Procedure C, providing full compliance with the standard while maximizing performance and automation.

Advancing Karl Fischer Titration with ECH

ECH has consistently supported developments in ASTM D6304, offering instrumentation tailored to each procedure. ECH systems enhance performance, extend reagent life, and simplify sample handling across a wide range of petroleum applications.

Original:

PIN PETROCHEMICAL CHEMICAL & ENERGY